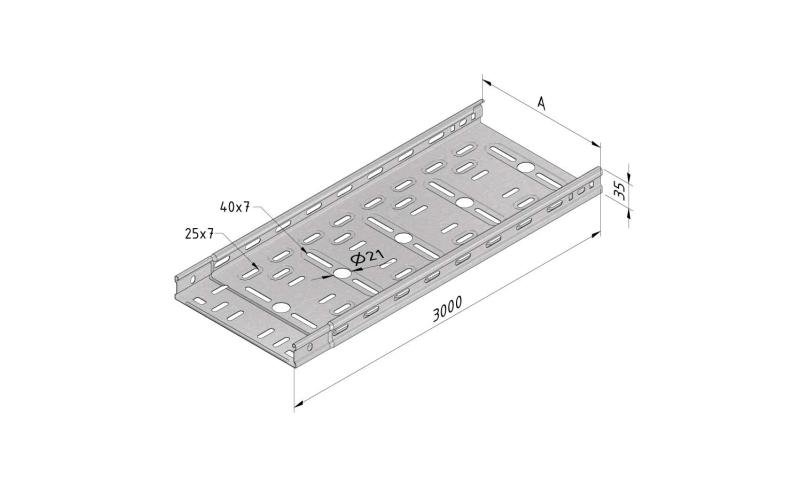

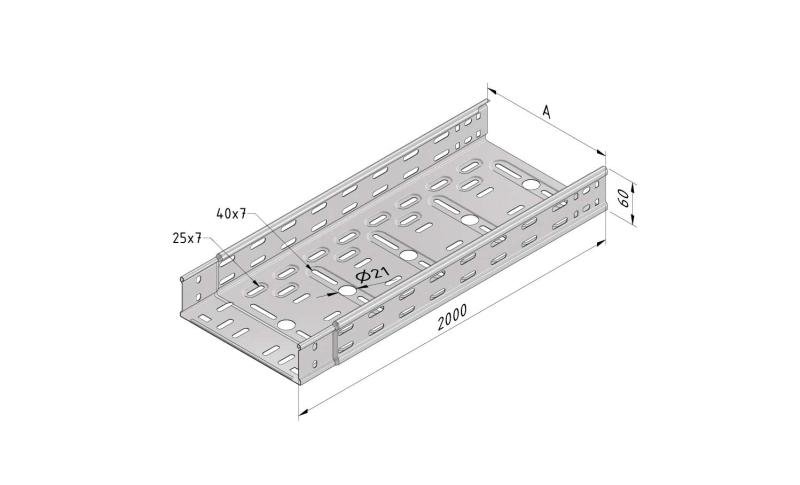

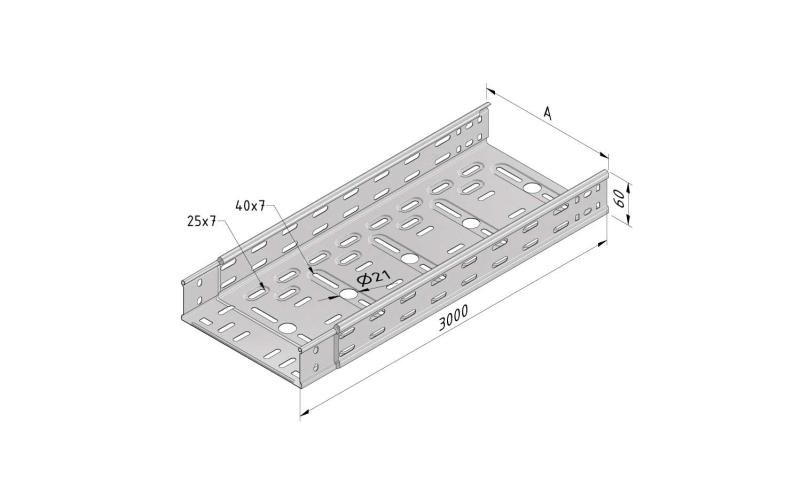

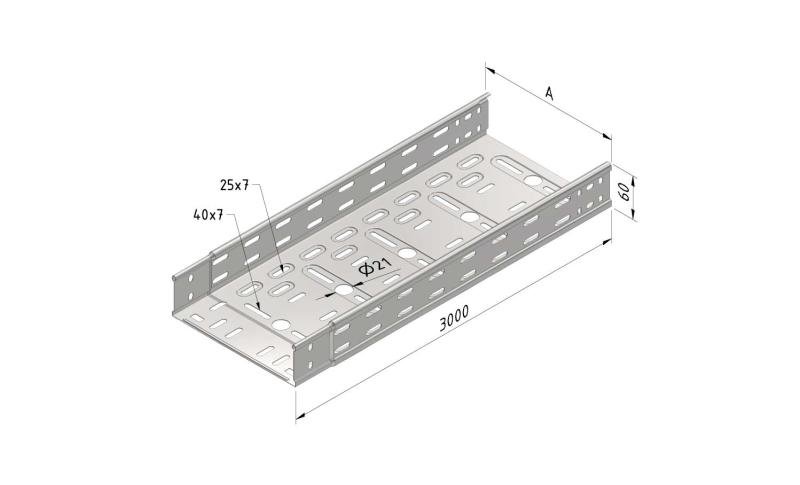

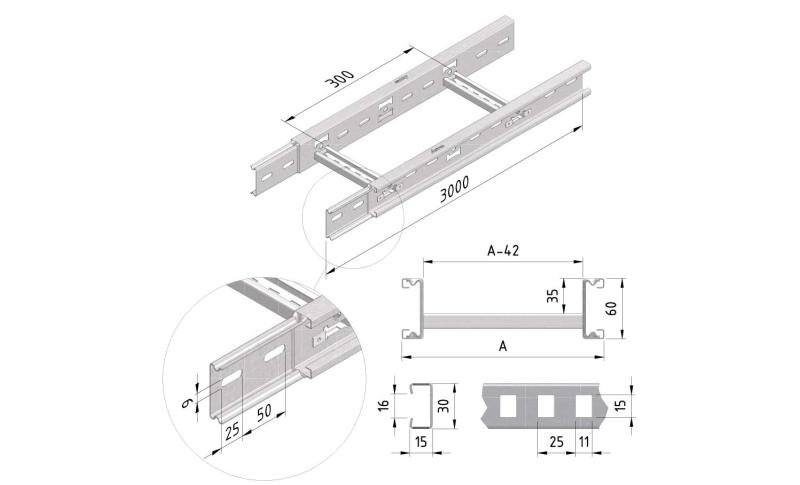

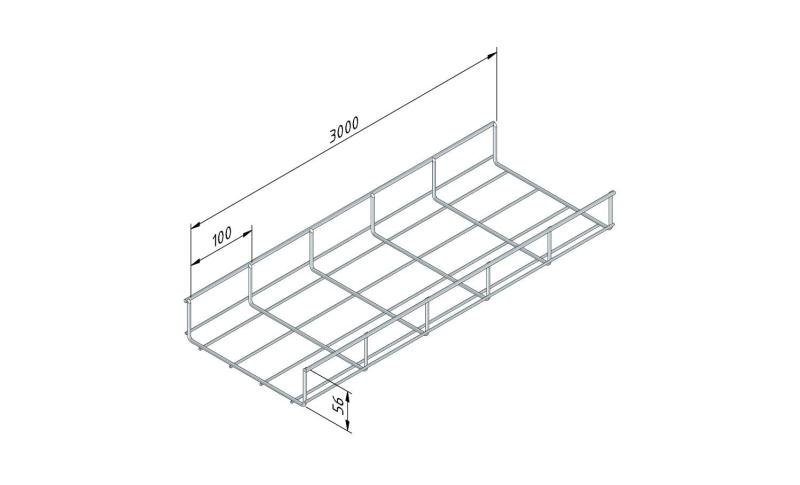

Wire Mounting Hole 45°

WM-S-SDA45

Wire Mounting Hole 45°

WM-S-SDA45

| SKU | Article code | Finishing | Dimension A | F (kN) | Packaging | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

12488 |

WM-S-SDA45-20-2EG |

EG

|

2000

|

0.45

|

10

|

Default

|

|

|||

Workload

Additional information

Finishing

Electrolytically galvanized (EN ISO 2081) EG (electrogalvanized)

Electrolytically galvanized products are mostly used in places where limited chemical contamination is likely, for example, in off ces, industrial buildings, covered parking lots, etc. Electrogalvanizing diff ers from hot-dip galvanizing in that the zinc coating, in this case, is built up by electrolysis. With this technique, there are no thermal infl uences on the steel, so no layers of alloy will form. Also, the coating thicknesses of 6-8µm (micron) are more limited compared to hot-dip galvanizing. Prior to the galvanizing, the steel sheet goes through several pre-treatment steps so as to ensure optimal adhesion (degreasing steps, pickling, a brief acid dip, multiple rinsing,….) After the galvanizing proper, the zinc coating receives a passivating- and dichromate coat, followed by a rinsing with demi-water. The advantages of electrogalvanizing are, among other things: no thermal deformation (so ideal for assembly parts), an attractive, uniform and perfectly smooth, high-gloss f nish with good electrical conductivity, no runs in the paintwork or zinc jags. |

|||||||||||

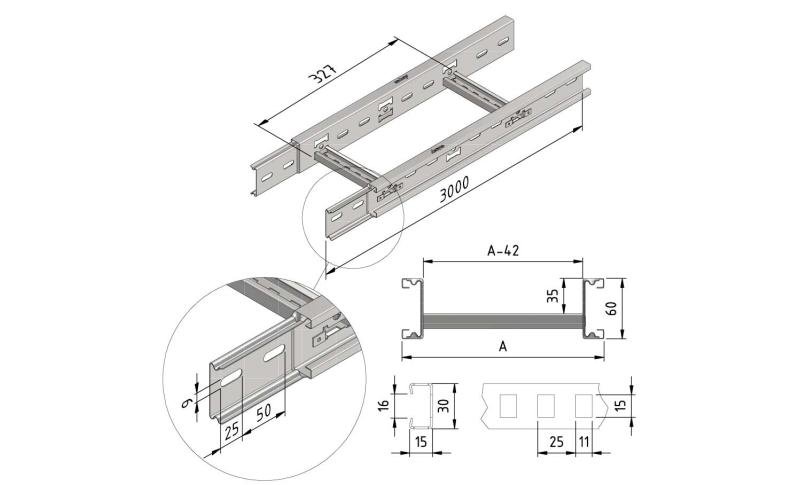

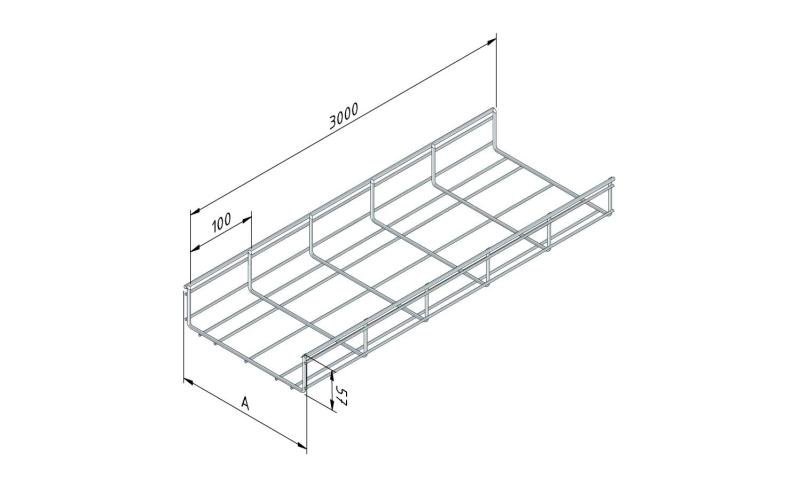

|

|

12489 |

WM-S-SDA45-20-3EG |

EG

|

3000

|

0.45

|

10

|

Default

|

|

|||

Workload

Additional information

Finishing

Electrolytically galvanized (EN ISO 2081) EG (electrogalvanized)

Electrolytically galvanized products are mostly used in places where limited chemical contamination is likely, for example, in off ces, industrial buildings, covered parking lots, etc. Electrogalvanizing diff ers from hot-dip galvanizing in that the zinc coating, in this case, is built up by electrolysis. With this technique, there are no thermal infl uences on the steel, so no layers of alloy will form. Also, the coating thicknesses of 6-8µm (micron) are more limited compared to hot-dip galvanizing. Prior to the galvanizing, the steel sheet goes through several pre-treatment steps so as to ensure optimal adhesion (degreasing steps, pickling, a brief acid dip, multiple rinsing,….) After the galvanizing proper, the zinc coating receives a passivating- and dichromate coat, followed by a rinsing with demi-water. The advantages of electrogalvanizing are, among other things: no thermal deformation (so ideal for assembly parts), an attractive, uniform and perfectly smooth, high-gloss f nish with good electrical conductivity, no runs in the paintwork or zinc jags. |

|||||||||||

No results

No results were found for your current search