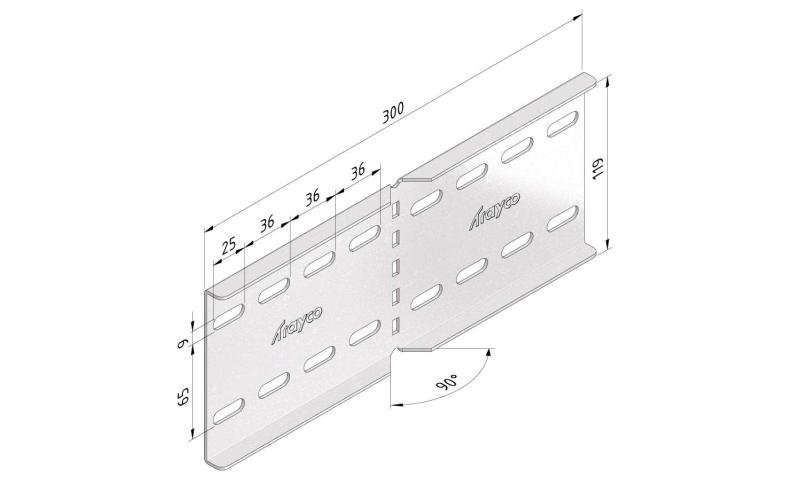

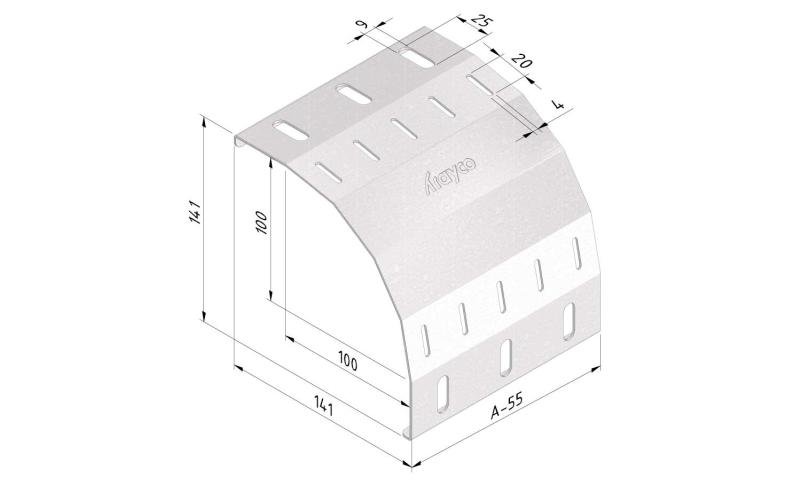

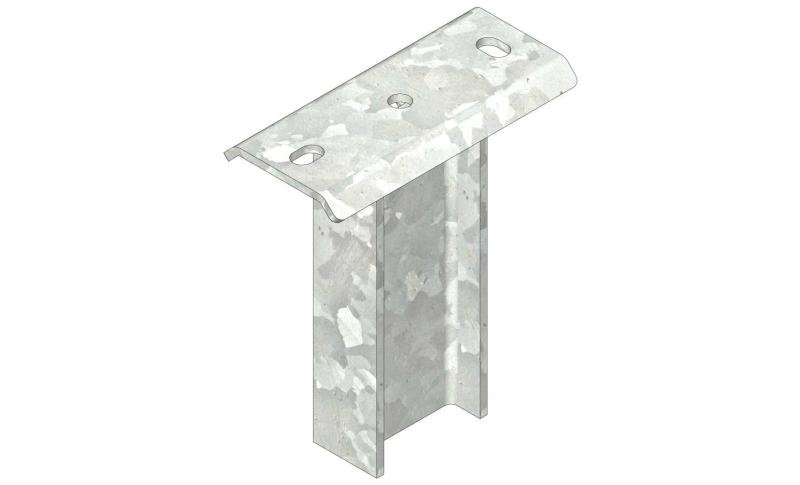

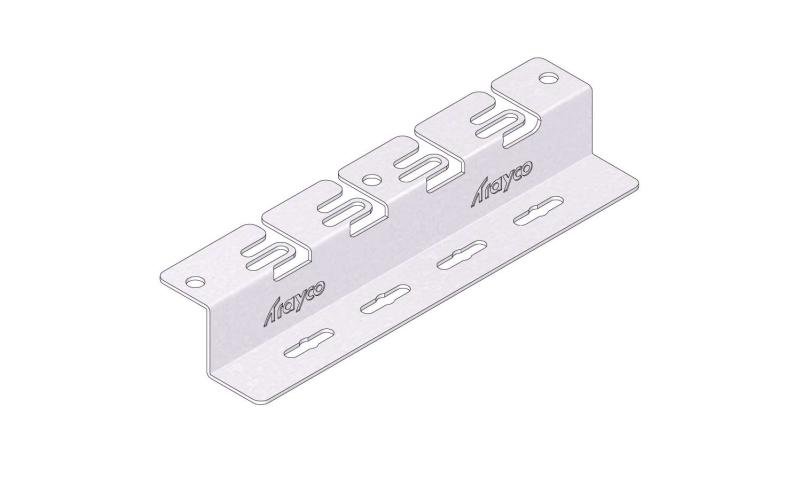

Cable ladder

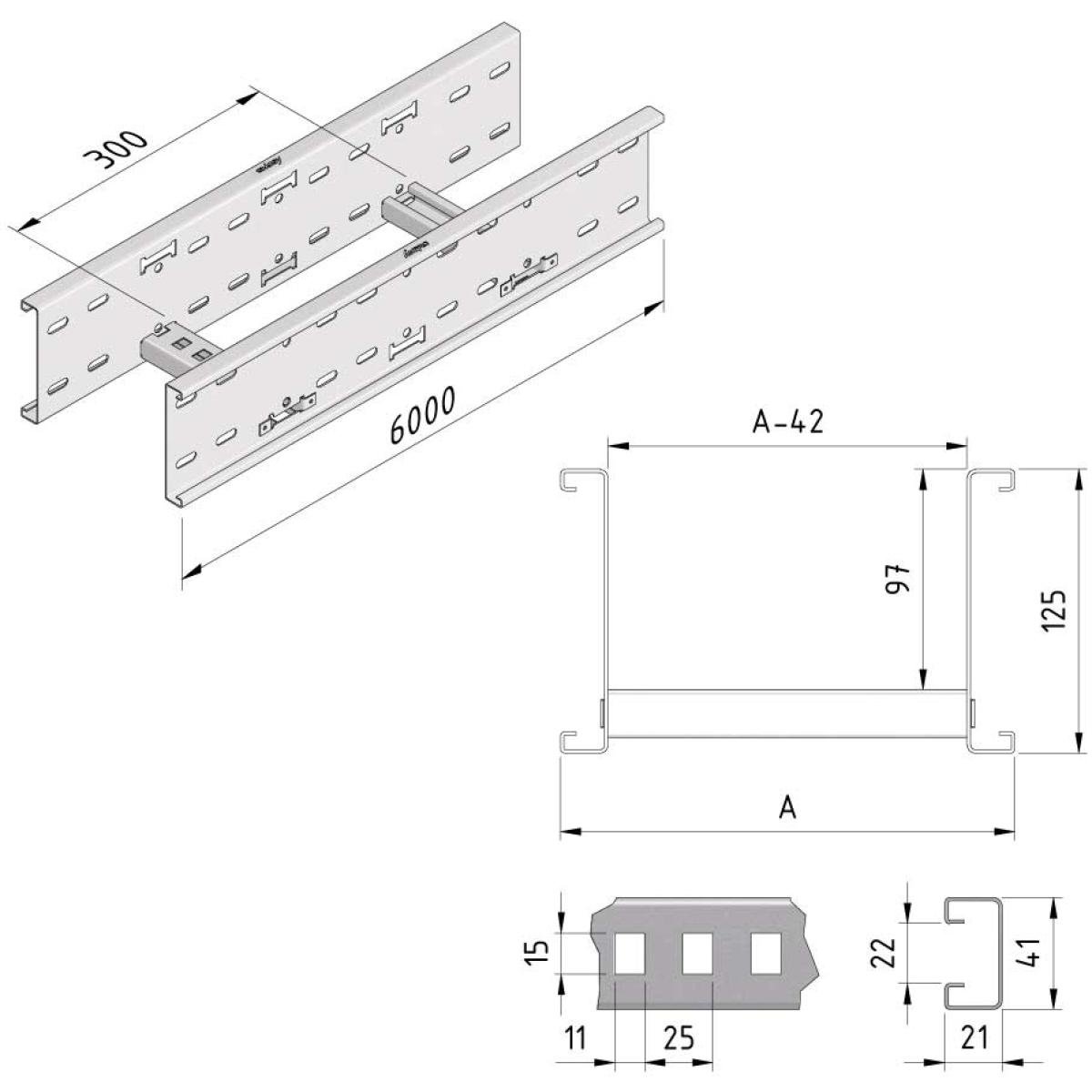

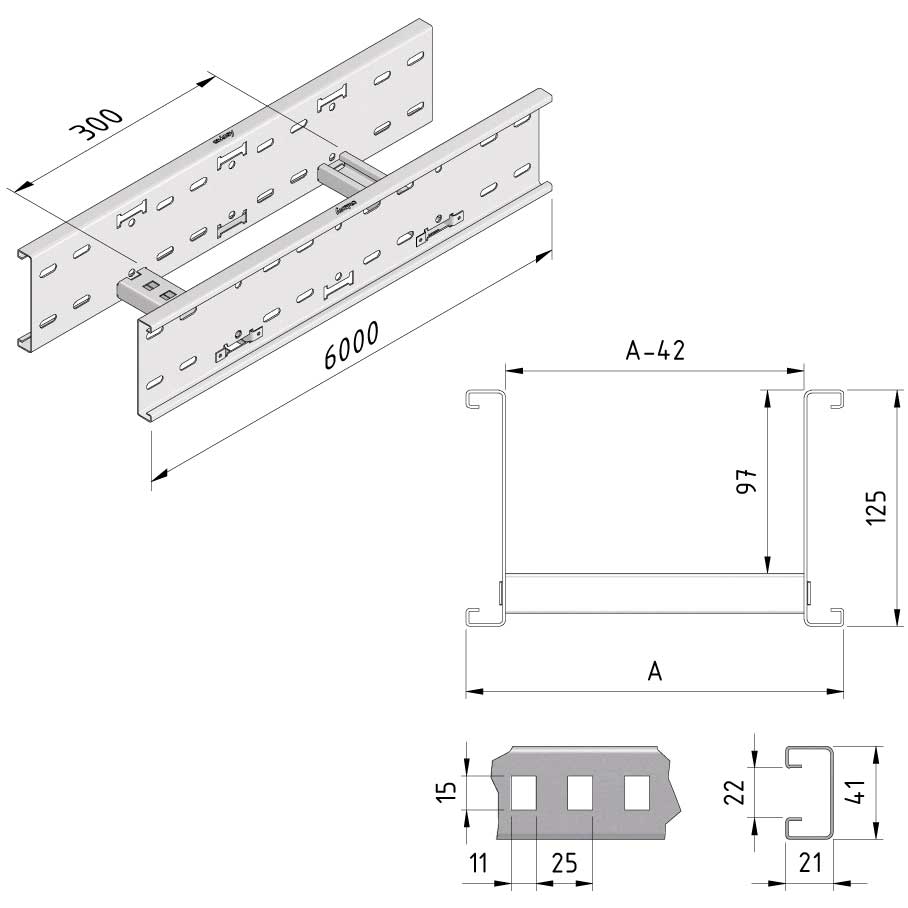

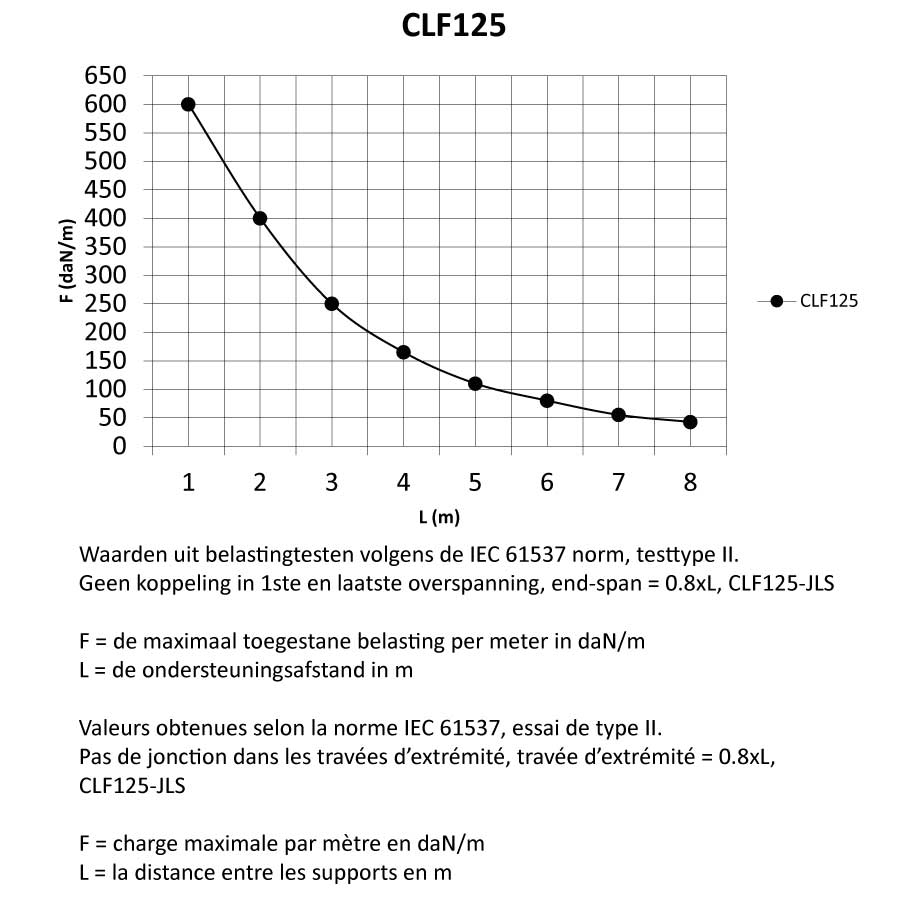

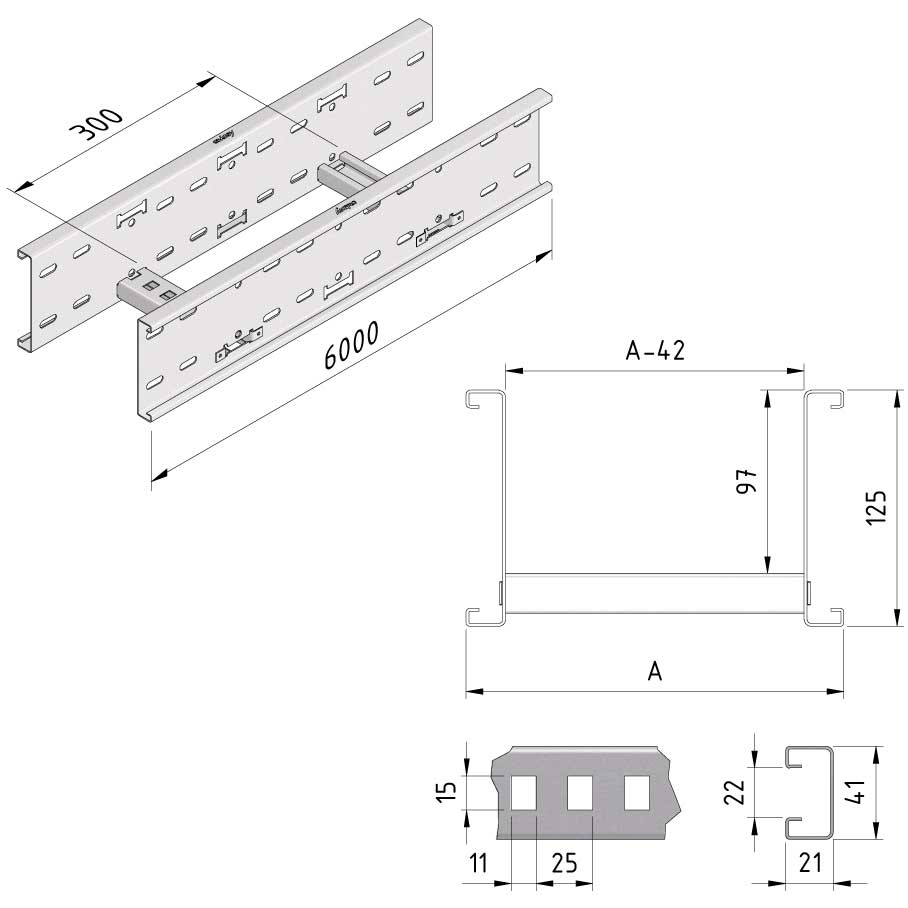

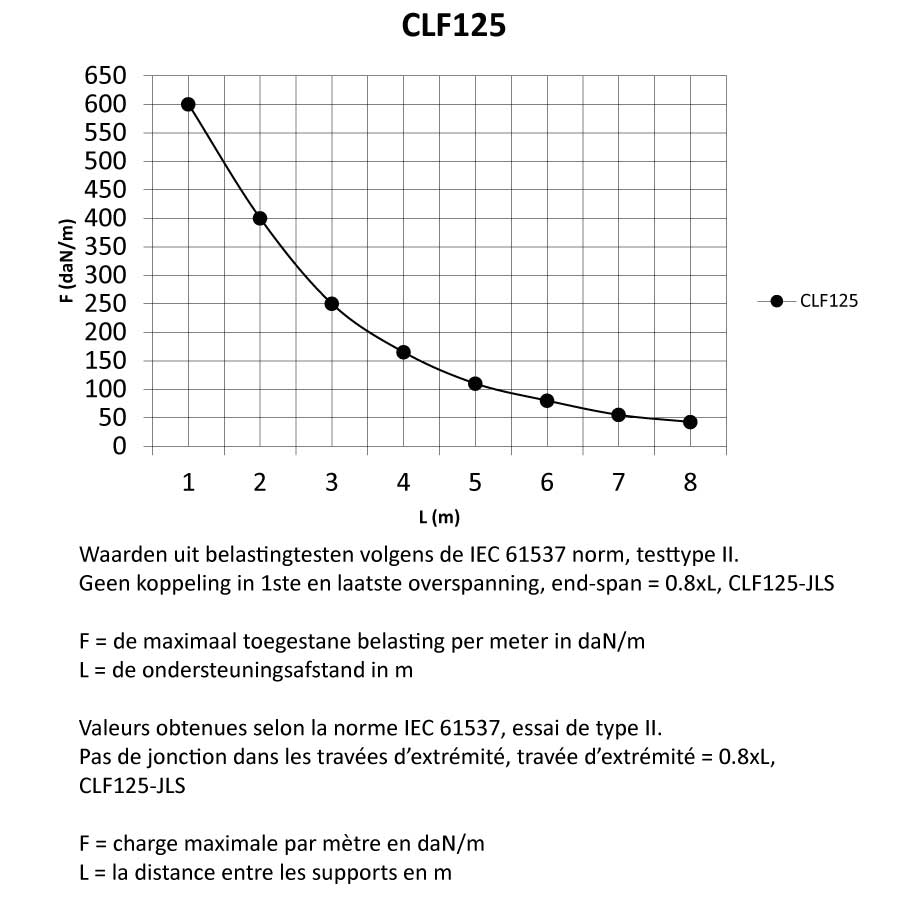

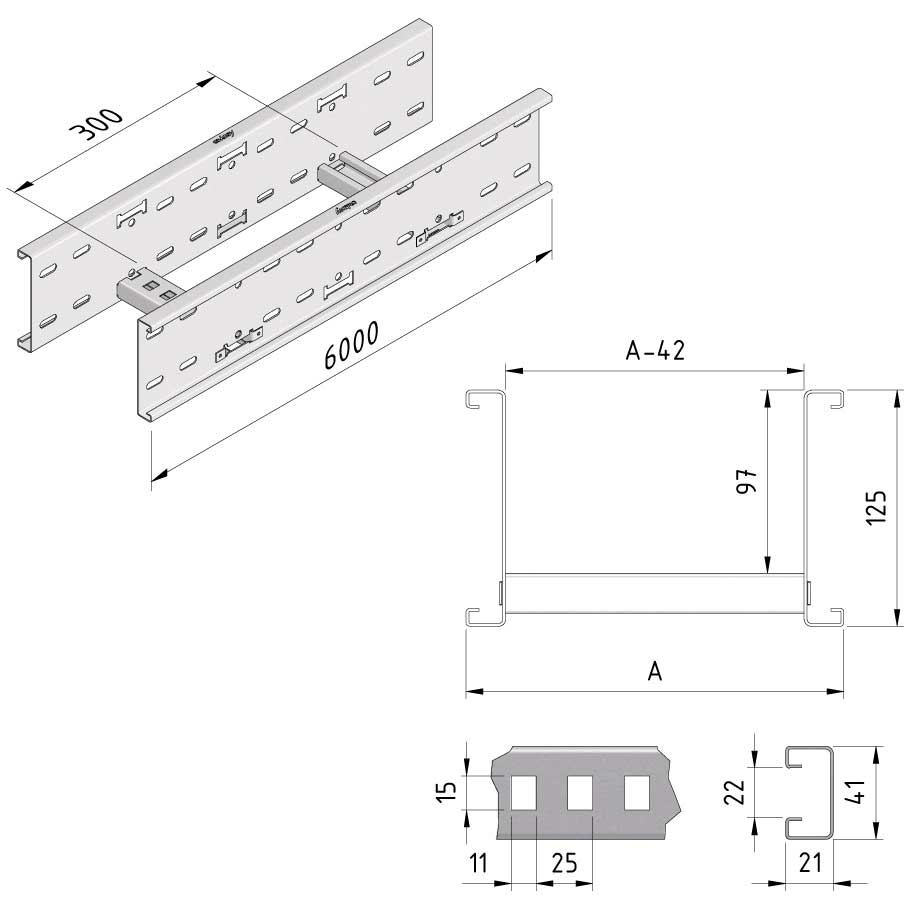

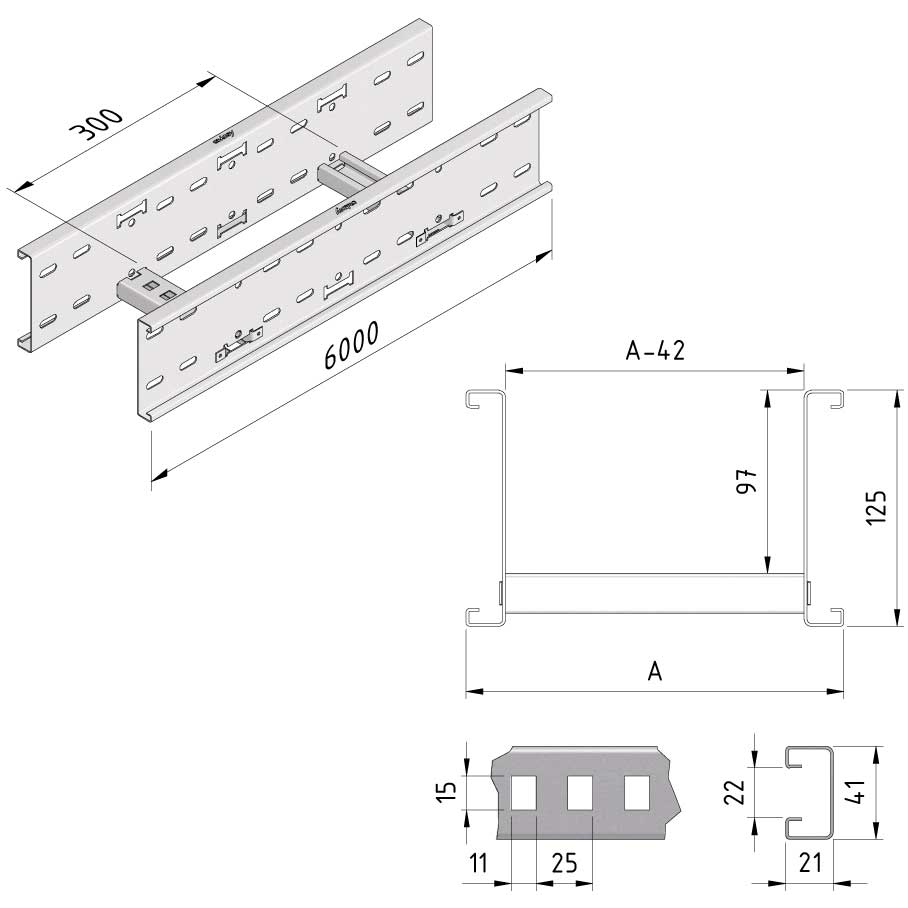

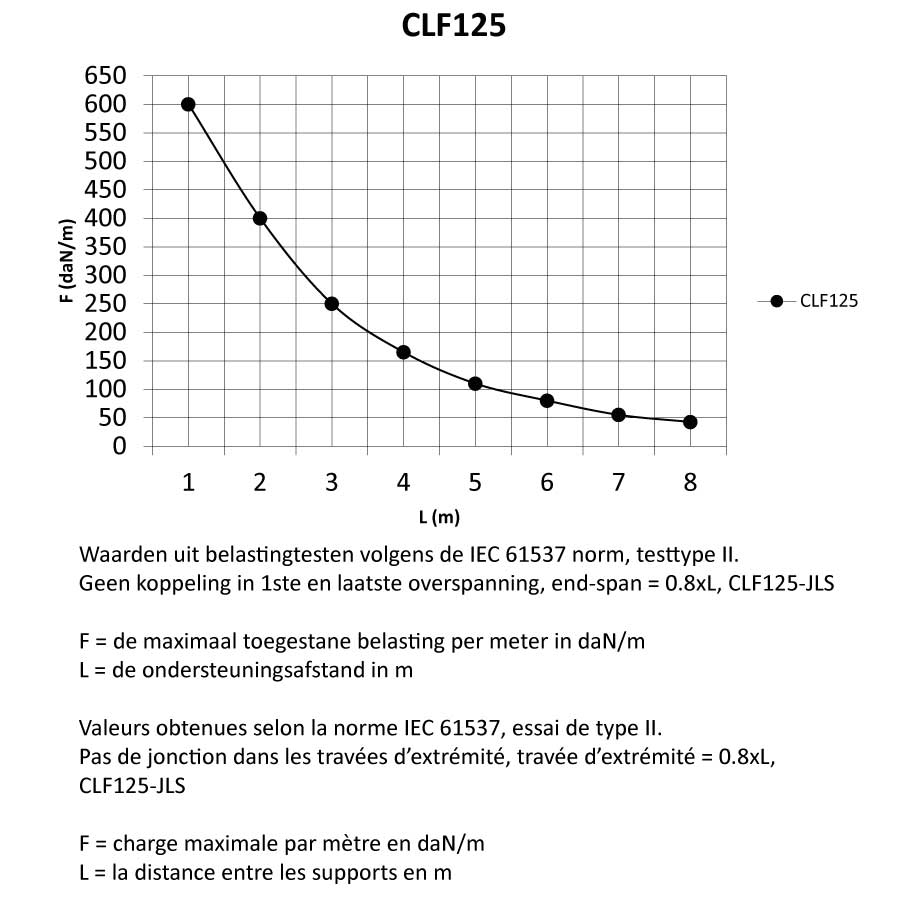

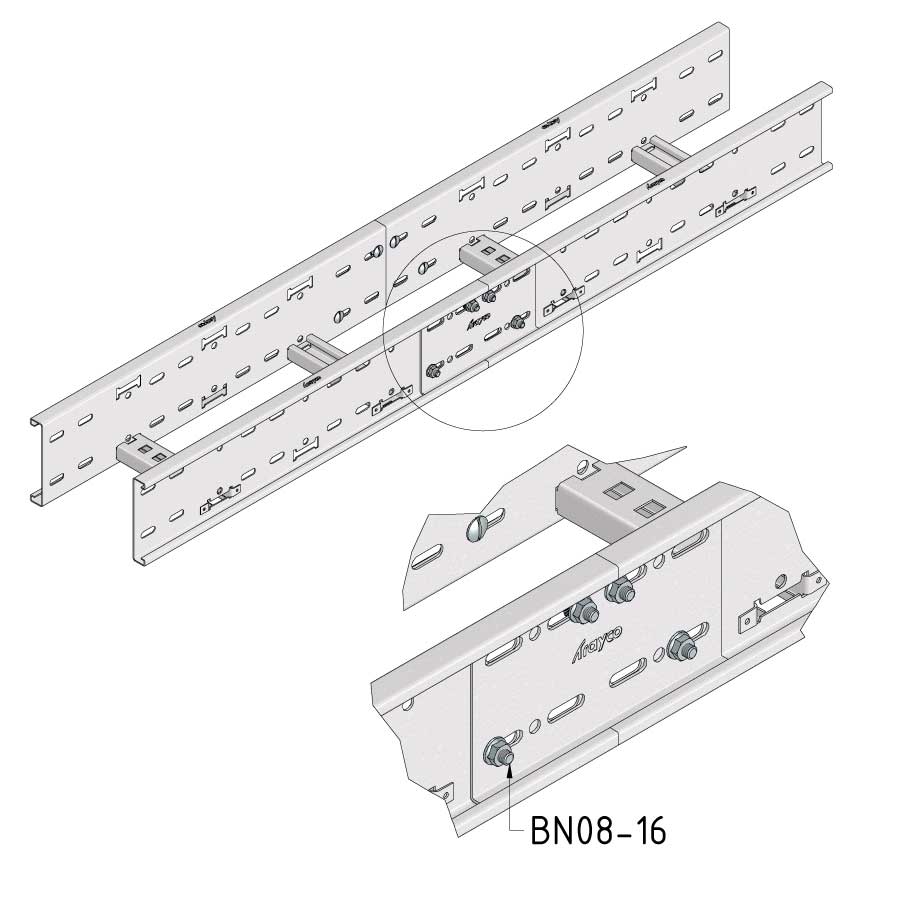

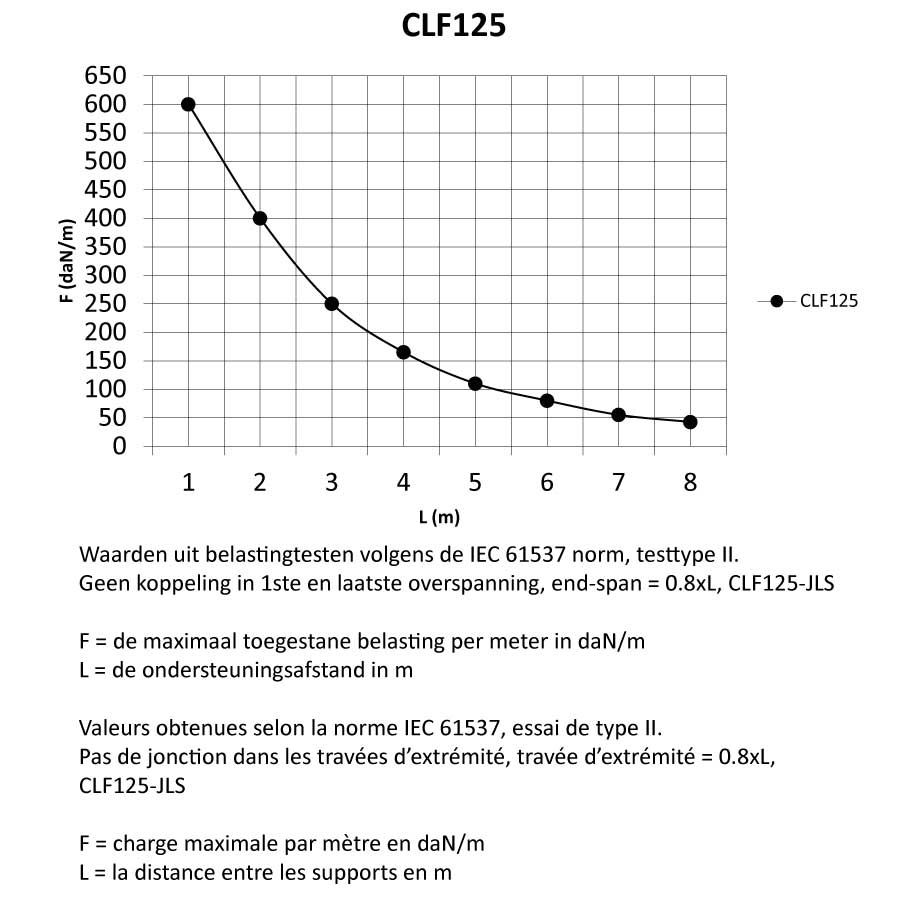

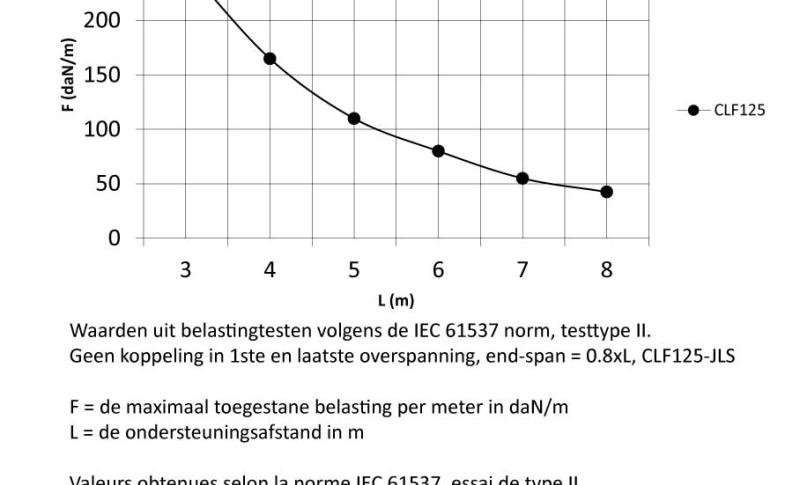

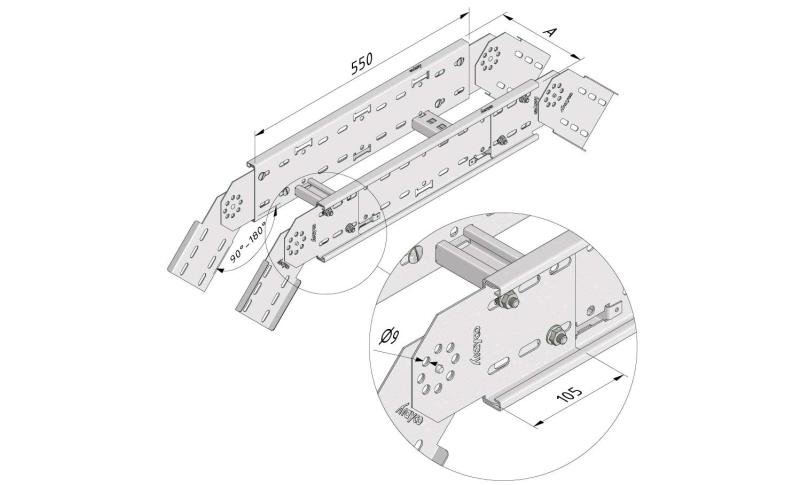

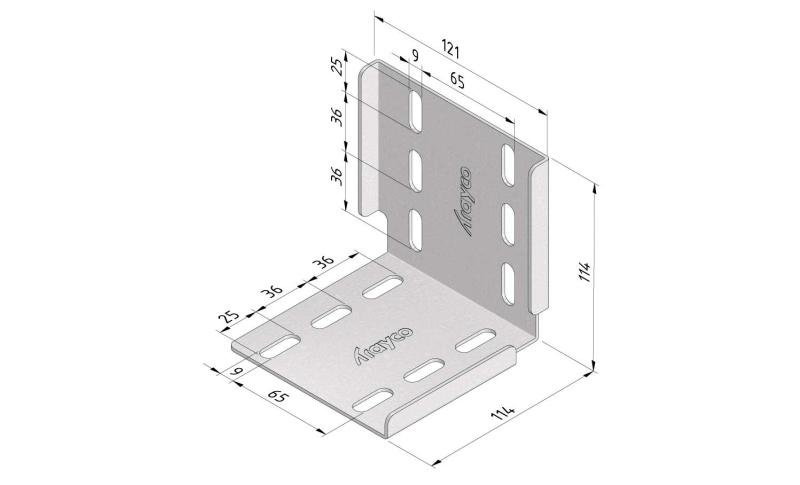

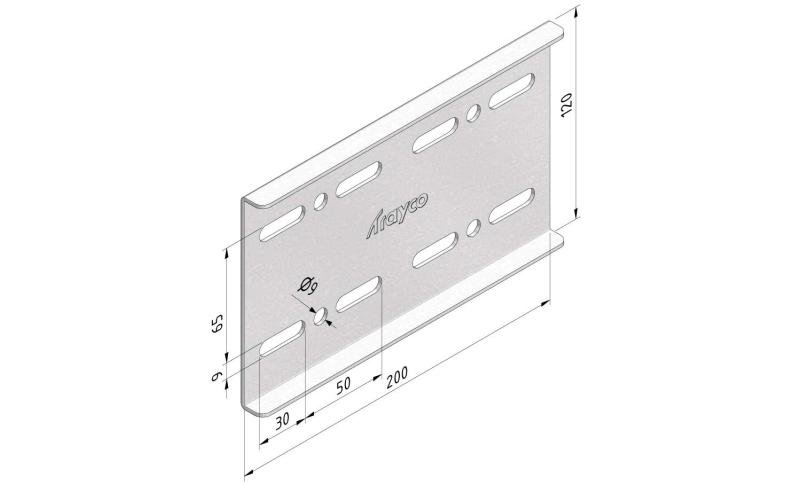

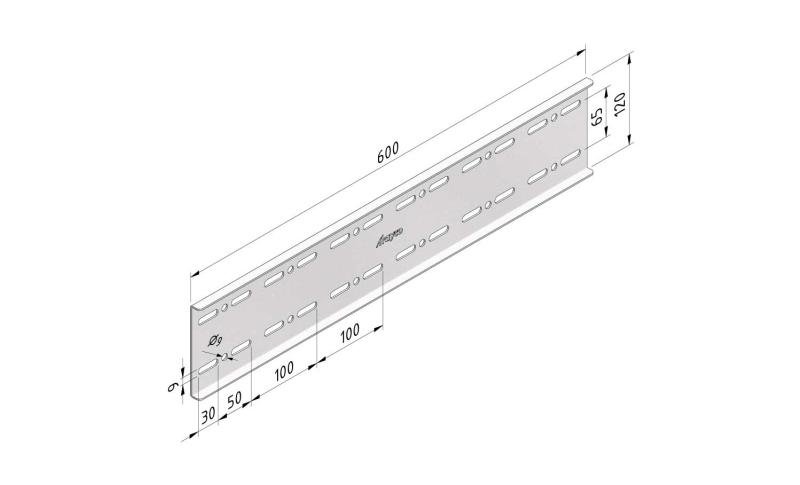

CLF125

Cable ladder

CLF125

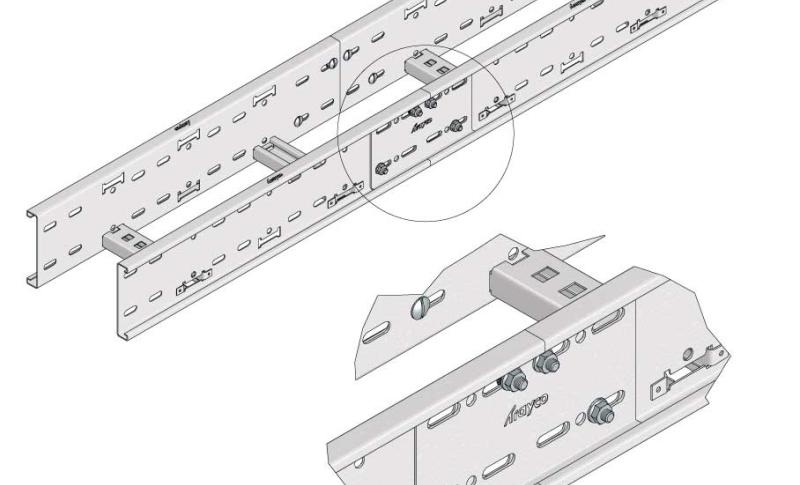

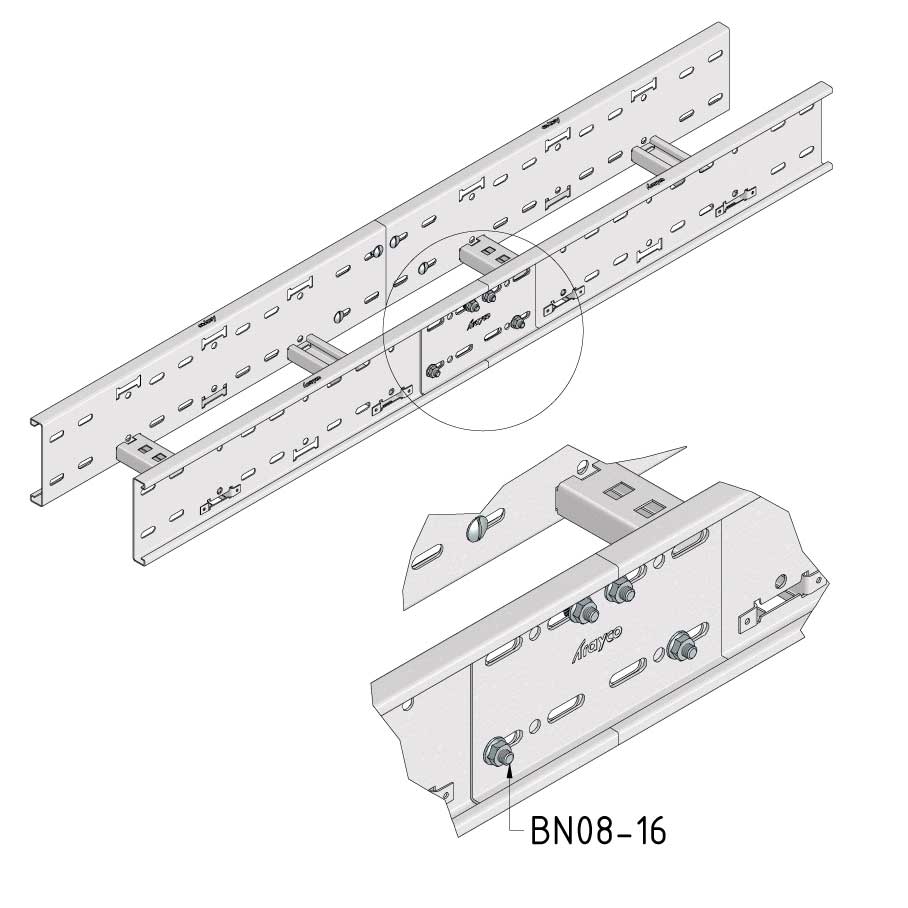

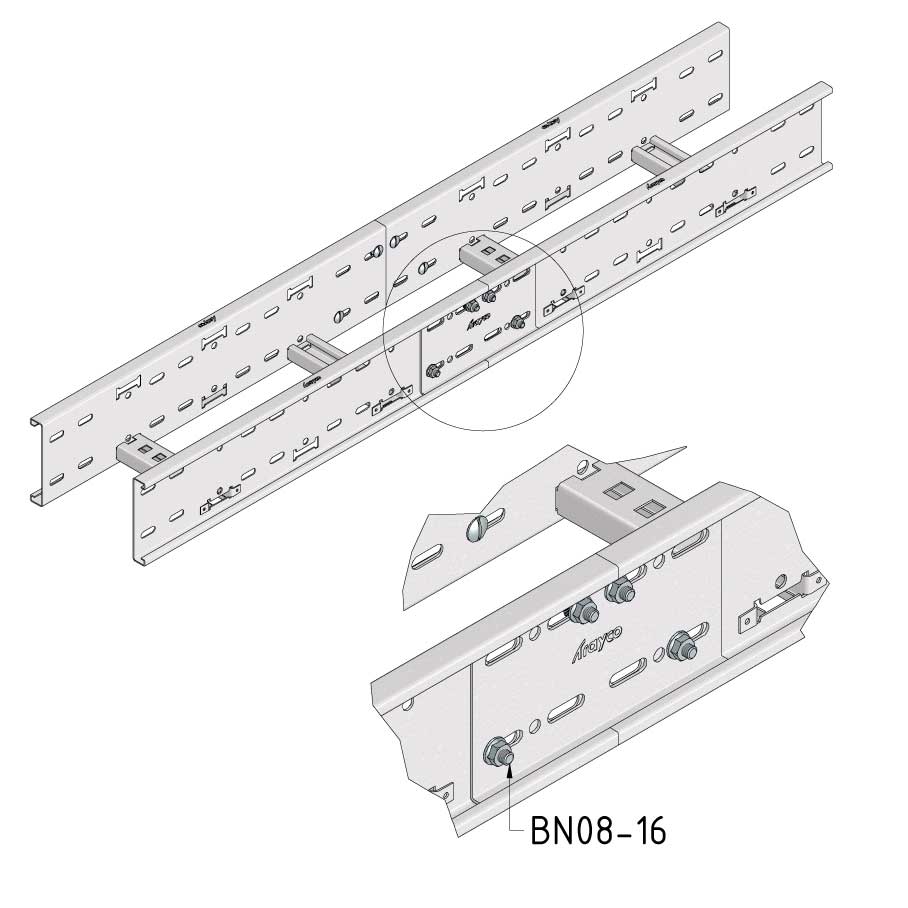

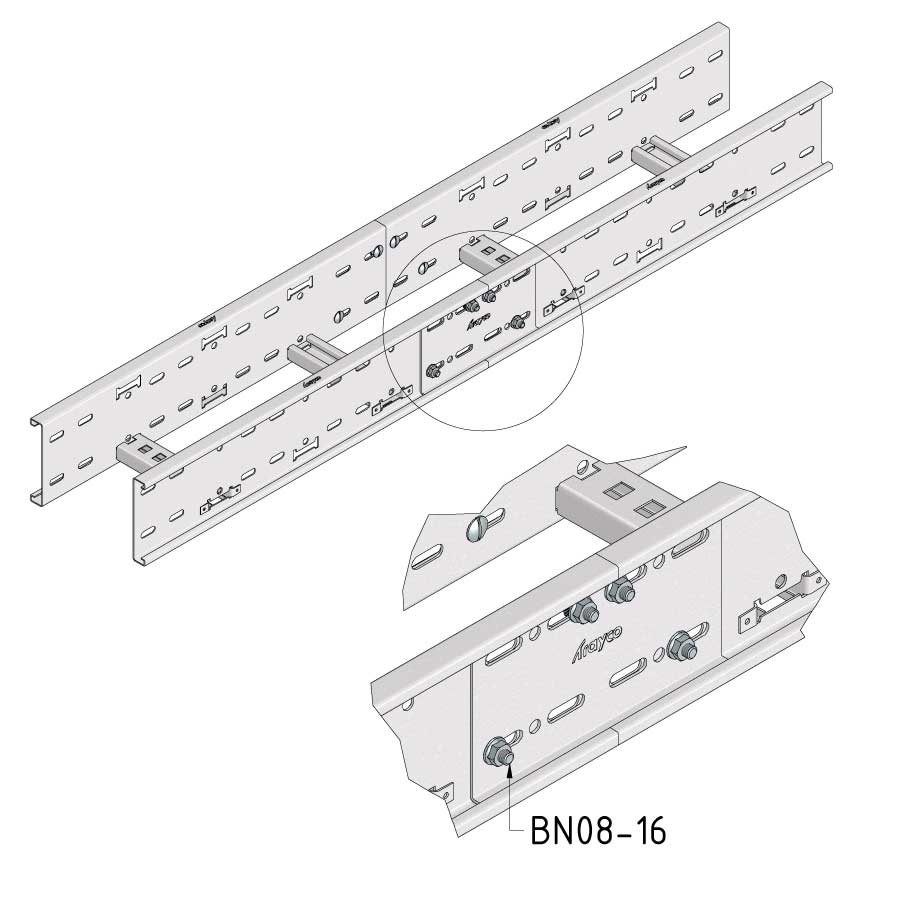

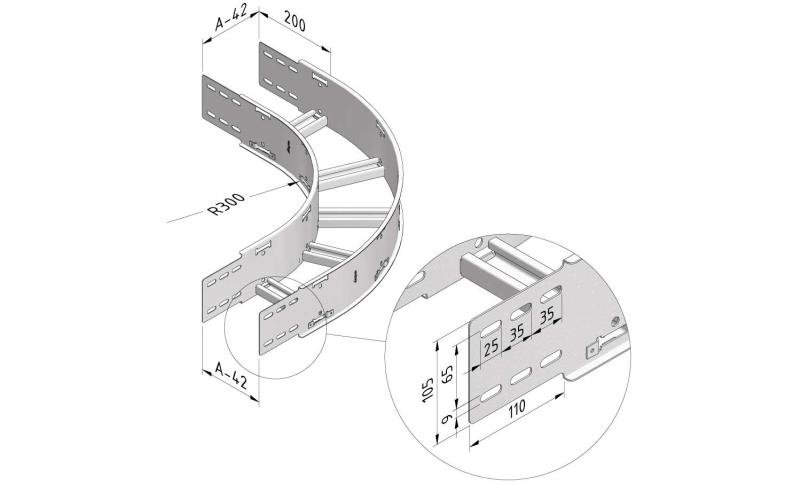

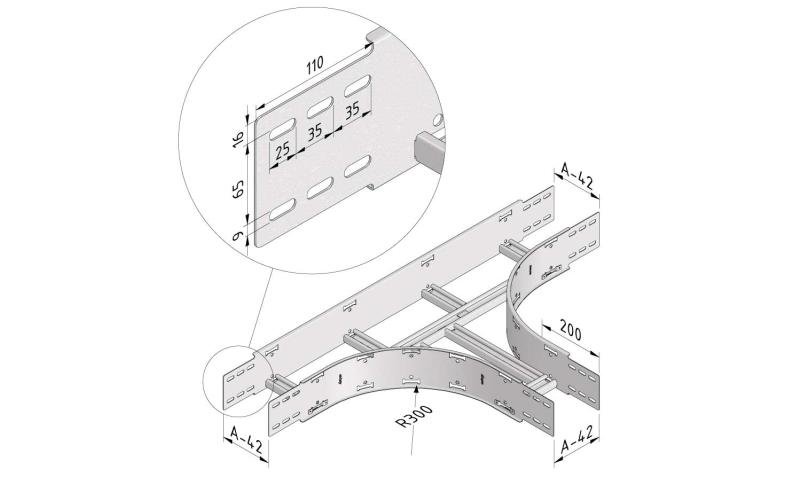

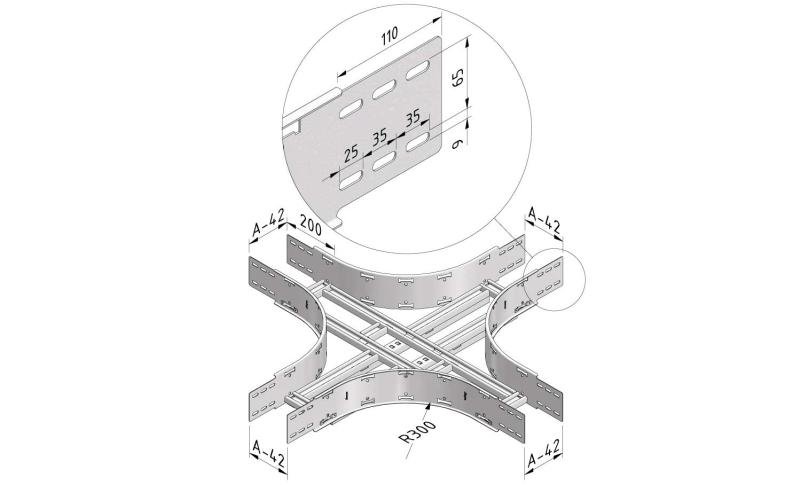

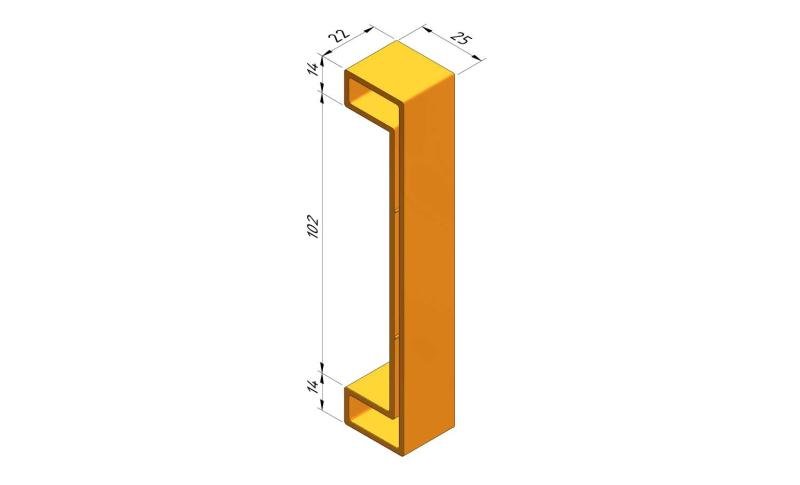

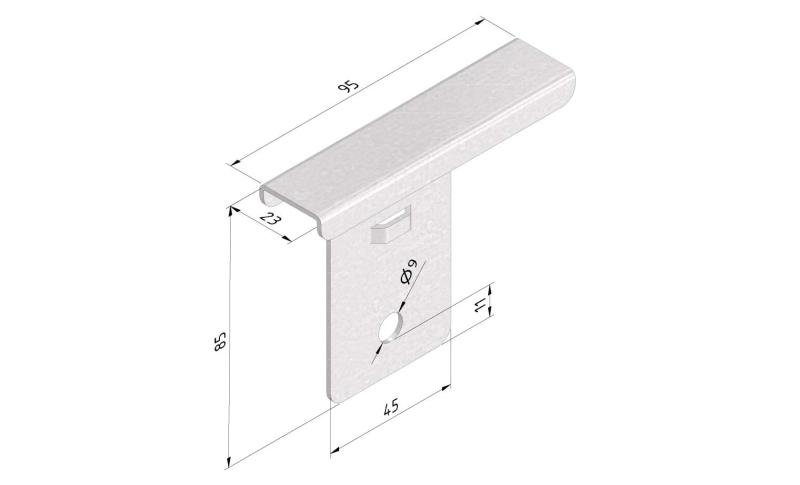

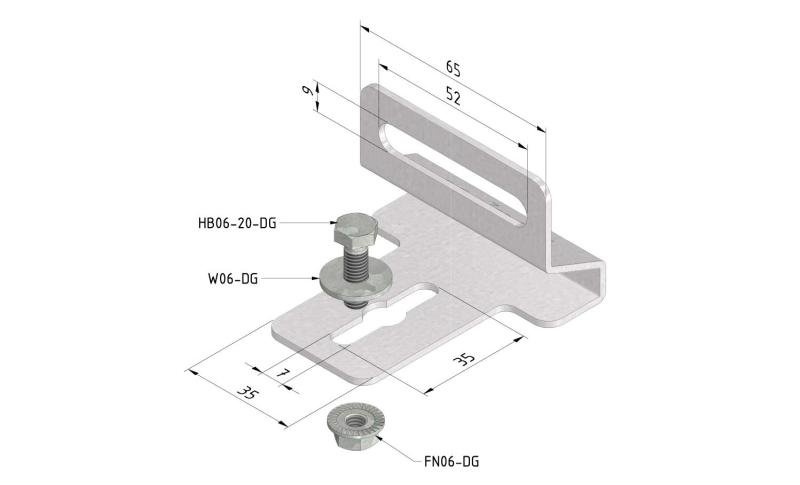

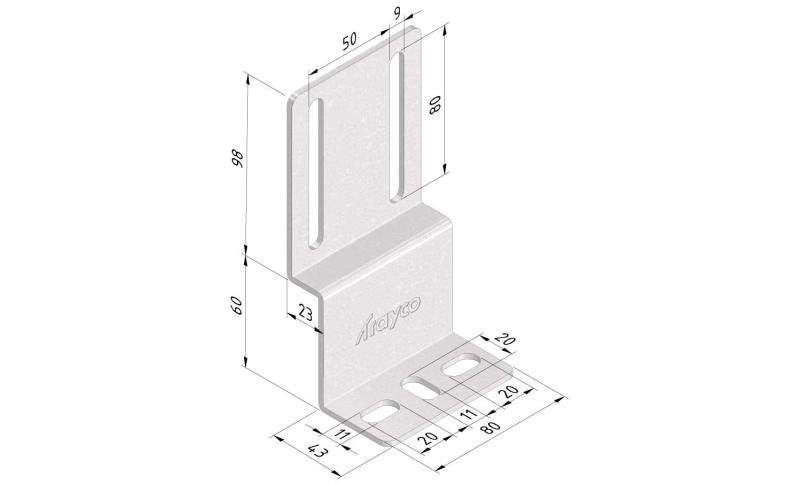

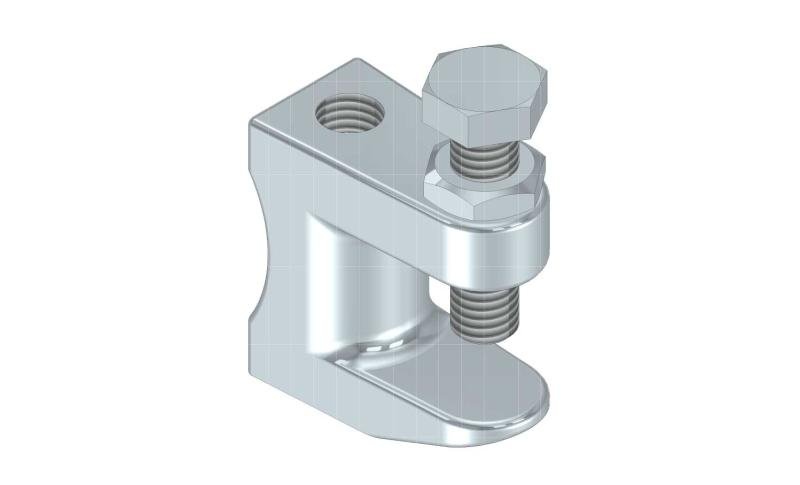

Connect with CLF125-J(LS) + BN08-16 / Fixation with CLF-BC

Coated finishing available on demand. RAL colour code to be confirmed on your order

| SKU | Article code | Finishing | Dimension A | Usable surface (cm²) | Packaging | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

20156 |

CLF125-0200-15-6UG |

UG

|

200

|

153.81

|

6

|

Default

|

|

|||

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

20157 |

CLF125-0300-15-6UG |

UG

|

300

|

250.24

|

6

|

Default

|

|

|||

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

20158 |

CLF125-0400-15-6UG |

UG

|

400

|

346.67

|

6

|

Default

|

|

|||

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

20159 |

CLF125-0500-15-6UG |

UG

|

500

|

443.1

|

6

|

Default

|

|

|||

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

20160 |

CLF125-0600-15-6UG |

UG

|

600

|

539.53

|

6

|

Default

|

|

|||

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

20455 |

CLF125-0800-15-6UG |

UG

|

800

|

732.39

|

6

|

Default

|

|

|||

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

20456 |

CLF125-1000-15-6UG |

UG

|

1000

|

925.25

|

6

|

Default

|

|

|||

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

No results

No results were found for your current search